De Waal offers various connection techniques for connecting the rudder blade and the rudder stock (rudder shaft). Each technique has its own advantages. At sea in heavy seas, the construction has to withstand enormous forces. We always build in a high degree of safety and follow precisely defined production procedures.

Are you looking for a fixed construction or a demountable unit? Choose the welded 'shrink ring module', the classic 'flange construction' or our innovative 'Pacific construction'. Developed by the machine builders at De Waal.

Fixed rudder blade

The most commonly used type in inland shipping is a fixed rudder blade. In other words, a 'no-nonsense' rigid connection between the rudder stock and the rudder blade. Unique thanks to our shrink ring construction. We insert the rudder stock deep into the rudder blade, after which it transitions into a hollow pipe. At the point of greatest stress, at the top of the blade, we fit a thick steel ring. This is crimped securely onto the rudder stock. It is welded on the outside, so that no welding is required on the rudder stock itself! This reduces material stress.

Advantages: relatively inexpensive and absolutely crack-free. The correct and most popular construction in inland shipping.

Removable rudder blade

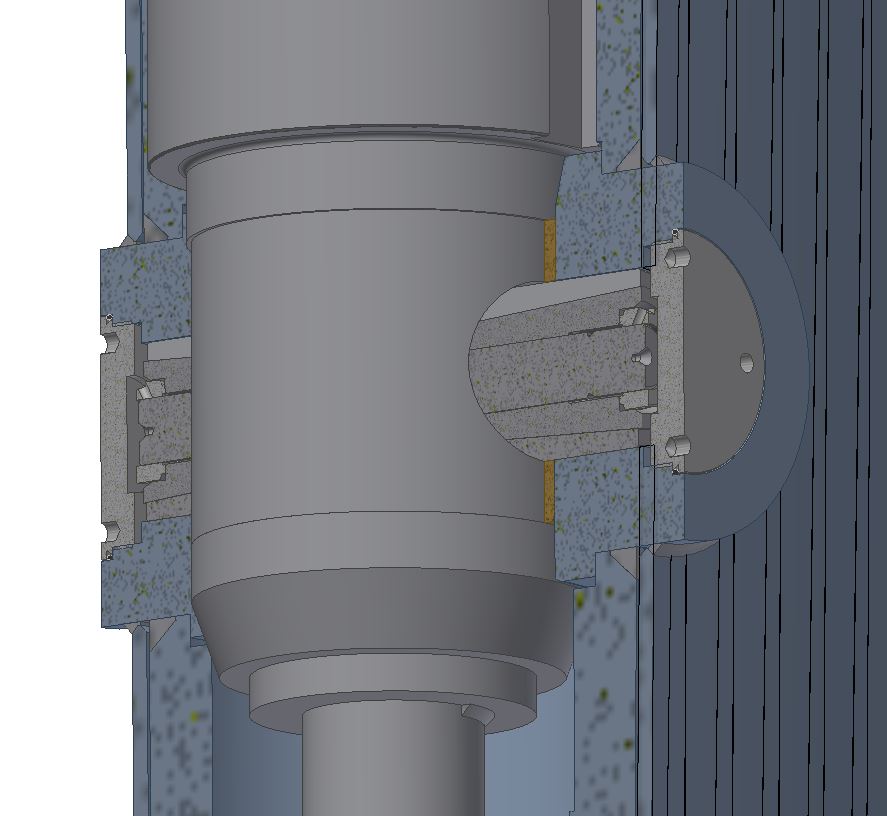

Prefer a demountable rudder blade? Then choose our 'flange construction' or 'Pacific construction'. Both designs have specific properties and advantages. The flange construction has traditionally been the most commonly used. On top of the rudder blade is a thick flange with multiple holes. An identical, round flange is attached to the underside of the rudder stock. By installing high-quality bolts, under preload, in the flange holes, a solid construction is achieved. Advantages: classic flanges, a removable and relatively inexpensive solution. Disadvantage: welding stresses at the flange transitions. Nevertheless, a widely used and durable, removable solution. Pacific construction The 'Pacific construction' has a favourable rudder stock that is inserted deep into the rudder blade. The end is located near the rudder centre, locked in place by a conical seat and secured by our unique hydraulic pin. This is a unique construction in shipbuilding. Due to the absence of flanges protruding from the rudder blade, this construction is ideal for superyacht building. But it is also suitable for the maritime sector, where high demands are placed on dismantlability.

Advantages: Time savings during disassembly and assembly, no welding stress in the rudder stock. Due to the absence of flanges, a more optimal flow profile and no 'gap loss' between the rudder blade and the rudder headbox. Long-term warranty on possible cracking of the rudder stock.